TOTAL PRODUCTIVE MAINTENANCE WORKSHOP

TOTAL PRODUCTIVE MAINTENANCE WORKSHOP

A Lean Total Productive Maintenance Workshop organized for key managers and officers of 5 major companies within the West and East African regions. The workshop was financed and facilitated by the American Soybean Association/World Initiative for Soy in Human Health (ASA/WISHH) with support from Yedent Agro Group of Companies.

The programme was made possible from initial engagements between Yedent and ASA/WISHH. The result was a collaboration between the consultants from Collaborative Impact and the project owners.

.

TRAINING GOALS & OBJECTIVES

The training goals and objectives were designed to ensure that at the end of the workshop, trainees would be able to:

• Identify wastes in their companies and specifically their job roles

• Apply the waste minimization tools to reduce waste and maximize process, people, raw materials and equipment effectively

• Transfer knowledge of all lean management principles and tools in plant and equipment maintenance.

BACKGROUND ON PARTICIPANTS:

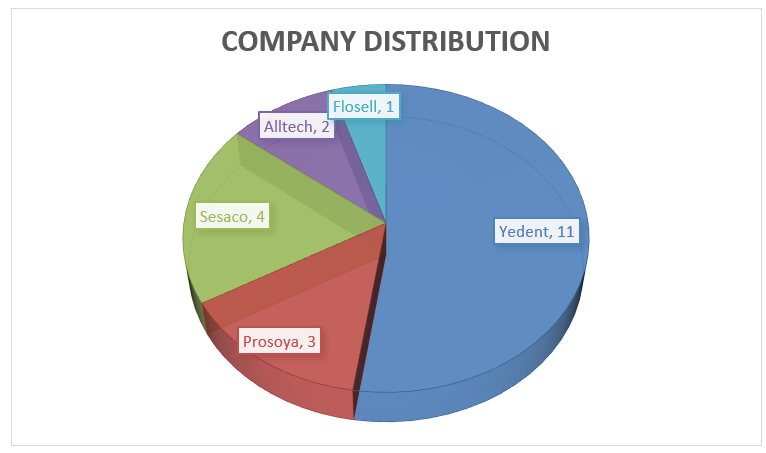

The workshop pulled 21 participants from 5 companies within the Western and Eastern African regions, specifically Kenya, Uganda, Nigeria and Ghana. The names of the companies are as follows:

• Alltech (Nigeria)

• Sesaco (Uganda)

• Prosoya (Kenya)

• Flosell (Ghana)

• Yedent (Ghana)

Through out the five (5) days the sessions were led and facilitated by Terri Lawrence, a Lean Expert and she was co-assisted by Carroll Rhea, a Lean Specialist. Learning sessions were mainly based on practical applications and feedbacks executed using the following approaches:

• Mini Lectures

• Field work

• Group work

• Team presentations

BACKGROUND ON PARTICIPANTS:

The workshop commenced with an orientation of participants on Yedent safety protocols to be observed whilst on site. This was followed by a welcome address and a brief introduction to Yedent and its operations by the Chief Executive Officer and General Manager respectively. Representing companies were given the opportunity to talk briefly about their companies and its activities; which was followed by introduction of training participants in the following order:

• Name

• Position/Job Role

• Lean exposure

• Hobbies

A tour of the factory and inspection of selected equipment was embarked on to help the participants familiarize themselves with the facility and equipment for the practical session of the workshop.